Introduction

Introduction Parameters

Parameters Installation design

Installation design Services

Services

Purpose and

scope of application:

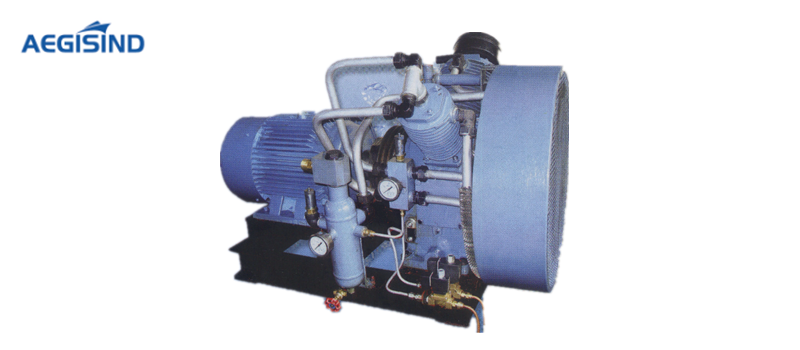

VLH-53 air

compressor is mainly used to start both the marine and land diesel

engines and also as the general compressed air source for pressure test and

other high pressure applications.

Structure

type:

VLH-53 air

compressor is V type vertical air-cooled 2-class compressor

Product

Features:

Features: The compressor has compact structure, V type

double cylinder,self balancing and small vibration. This compressor adopts fan forced

cooling tube fin cooler,it has good cooling performance and it is reliable-operation in

marine conditions.

Unit

description:

1.This can be

direct driven or belt driven,or diesel engine belt driven,has a common base

with oil-water separator,pressure controller,unloading electromagnetic

valve,and it also can match temperature control device, shock absorber,exhaust

hose and so on.

2.This can match wall-hanging electric cabinet,which can realize automatic unloading, automatic starting, automatic stopping,motor overload,exhaust high temperature alarm and stop and so on.

| VLH-53 air compressor principal specification | ||||||

| Compressor model | VLH-53 | |||||

| Type | 90° V type、air-cooled、2 stage compression | |||||

| Number of cylinder | 2 | |||||

| Pressure rating(Mpa) | 3 | |||||

| Rotation rating(r/min) | 900 | 1000 | 1200 | 1500 | ||

| Quantity of air supply(m3/h) | 45 | 50 | 60 | 74 | ||

| Suction filtration method | Dry filter element | |||||

| Lubricating system | Splash lubrication | |||||

| Oil capacity(L) | 6.8 | |||||

| Method of driving | Direct coupling or V-belt drive | |||||

| Type of un-loader | Manual un-loader or magnetic un-loader valve | |||||

| Motor | Model | Direct coupling | Y180L-8-H | Y180L-6-H | Y180L-6-H | Y180M-4-H |

| Voltage/Frequency(V/Hz) | 440/60 | 380/50 | 440/60 | 380/50 | ||

| V-belt drive | Y160M-4-H | Y160L-4-H | Y160L-4-H | Y180M-4-H | ||

| Voltage/Frequency(V/Hz) | 440/60 or 380/50 | |||||

| Rotation rating(r/min) | Direct coupling | 880 | 970 | 1180 | 1470 | |

| V-belt drive | 1460 | 1460 | 1460 | 1470 | ||

| Power(kw) | 11 | 15 | 15 | 18.5 | ||

| Dimension(mm) | 1250×860×840(Direct coupling) | |||||

| 1450×700×920(V-belt drive) | ||||||

| Weight(kg) | ~450 | |||||

Placement of Installation and Intake Air

Install the compressor possibly nearest to the site of

service. If site of service lines

scattered, install the compressor collectively around the center of lead to

minimize piping resistance and leakage and save the cost of installation.

Also Please note that well lighted space helps you find

earlier leakage and abnormal as well as perform maintenance service smoothly,

while Quiet environment enables to detect even a slight abnormal sound,

preventing possible troubles.

Ample passage provides and facilities security,

disassembly work and maintenance and inspection. At least, space of 1 meter

should be reserved around the compressor. In most cases air intake includes

dust. It is known by analysis that half of the carbon deposit on the valve is

dust. These faulty conditions would cause

leakage from cylinder or piston, or malfunction of valve, finally efficiency

down and great troubles.

Air Delivery Piping

High temperature rise in delivery pipe line would cause

thermal expansion. Therefore, piping should be installed in such a manner that

it can absorb contraction or expansion.

(1) For this purpose, the use of more than two bends on

the midway of pipe line is recommended. Where one piping section is so long,

the pipes should be supported with appropriate pipe supports.

(2) Arrange delivery pipe as short as possible.

(3) Stop-valve should not be installed in the midway of

delivery pipe. If it is needed to be done, safety valve must be fitted between

the compressor and the stop valve. Safety valve used for this purpose should be

large enough to release all the Compressed air.

Electric Wiring

Wiring must be installed correctly by qualified engineers

or contractors in conformity with applicable codes. Durability and insulation

tests should be done carefully while tools and materials used in wiring must

meet the requirements of standards. Electrical Motor starting method should be

selected according to power facilities of the plant. For details, consult with

contractor or our firm.

Aegis industry is a sino-foreign joint

venture which have factory and warehouse in China,Singapore,Bangladesh,Indonesia,India,USA,Canada,Greece

and so on.

AEGIS INDUSTRY

(SHANGHAI) CO.,LTD

Address:No.26

Zhoukang Road, Pudong Shanghai China 201318

Tel:0086-021

2097 5028

Fax:0086-021

2097 5062

E-mail:service@aegisind.com

website:www.aegisind.com

Call Center:+86 21 20975028 +86 21 20975062 Mobile:+86 136 716 88208 E-MAIL:sales@aegisind.com service@aegisind.com

All rights reserved, Copyright © 1998~2015, AEGIS INDUSTRY (SHANGHAI) CO.,LTD

沪ICP备19015827号-1